Enhancing the Tribological Performance of Additively Manufactured Aluminium Alloy ER 5356 via the Cold Deformation Process

DOI:

https://doi.org/10.37934/aram.113.1.189206Keywords:

Tribological performance, wire arc additive manufacturing, cold deformation, part repairAbstract

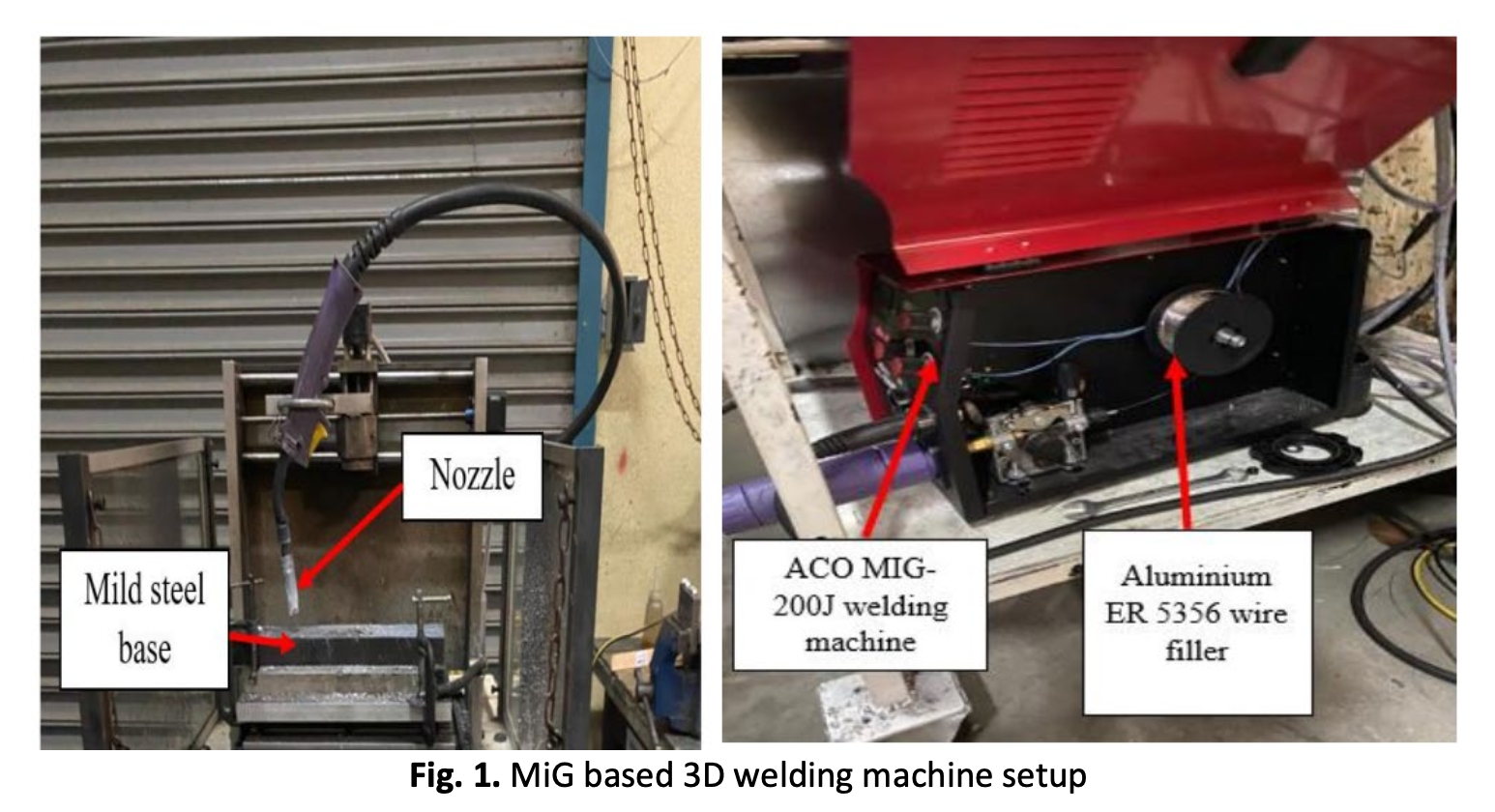

Typically, in handling worn parts, to avoid extra expenditure, car manufacturers will send them to the scrap yard. Reconstruction of the worn area via additive manufacturing is now an option. Unfortunately, heat will reduce the deposited material’s properties, like wear resistance. In this study, the effect of a cold deformation via cold forging on the tribological performance of aluminium alloy wire ER 5356 fabricated by wire arc additive manufacturing (WAAM) will be investigated. The cold forging process was conducted at room temperature on an open die transverse to the direction of the deposited weld. Comparisons were made between unforged and forged specimens at dry and wet sliding conditions at varied speeds and loads applied. Based on the results, it was observed that forged specimens exhibit a lower specific wear rate than unforged specimens for both conditions. The coefficient of friction (COF) in dry sliding decreases as the specific wear rate increases. However, comparatively, COF at wet sliding is lower for both unforged and forged samples. As a conclusion, the cold forging enhances the tribological performance by lowering the specific wear rate and COF.

Downloads