Analysis on the Performance of Designed Fluidized Bed Dryer for Drying Coffee Beans

DOI:

https://doi.org/10.37934/araset.31.1.99109Keywords:

Fluidized bed dryer, ANSYS, coffee beans, simulationAbstract

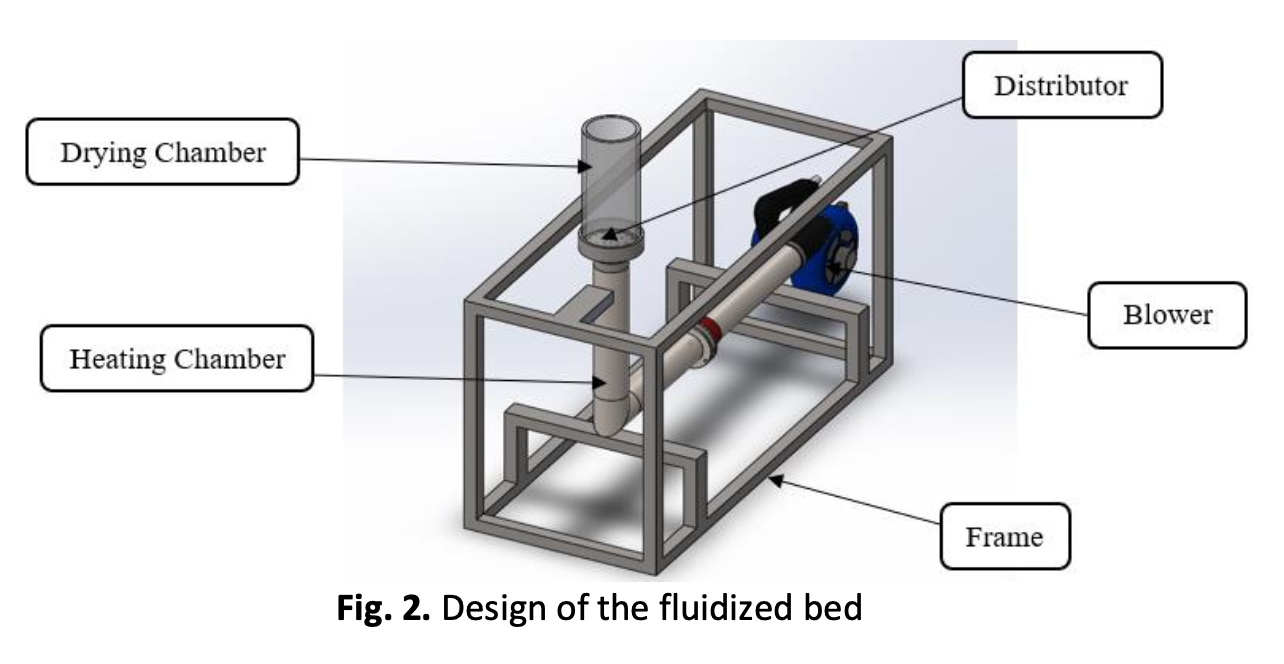

Drying coffee beans is an important role in the process of making coffee. Most coffee producers dry their coffee beans under the natural sun, but it was found to be time-consuming and depended on the weather conditions. Fluidized bed dryer is found to be the most recent method to dry the coffee beans. However, not many reported on the performance of fluidized bed dryer in coffee drying. In the present research, the quality of the drying process using fluidized bed dryer was investigated by varying the streamline pattern and temperature distribution in the drying chamber. The result was compared with a different temperature and velocity applied. The simulation in ANSYS was conducted with three different velocities of 10 m/s, 20 m/s and 30 m/s with air temperature of 60 °C, 90 °C and 120 °C. The temperature supply was from the inside of the pipe to the end of the drying chamber. The streamline and the temperature distribution were absorbed between the difference of temperature and the velocity difference. The computational analysis of the simulation showed that the increase in velocity resulted in a temperature rise from 46.72°C to 49.04°C within the drying chamber for constant inlet temperature of 60 °C, and on the other hand the velocity in the drying chamber remains constant at average of 3.22 m/s for inlet velocity of 10 m/s despite the increase in temperature.

Downloads