Impact of Geometrical Parameters on Heat Transfer Characteristics of SiO2-Water Nanofluid Flow through Rectangular Corrugated Channels

DOI:

https://doi.org/10.37934/arfmts.104.2.86102Keywords:

Corrugated channels, nanofluids, heat transfer, pressure drop, CFDAbstract

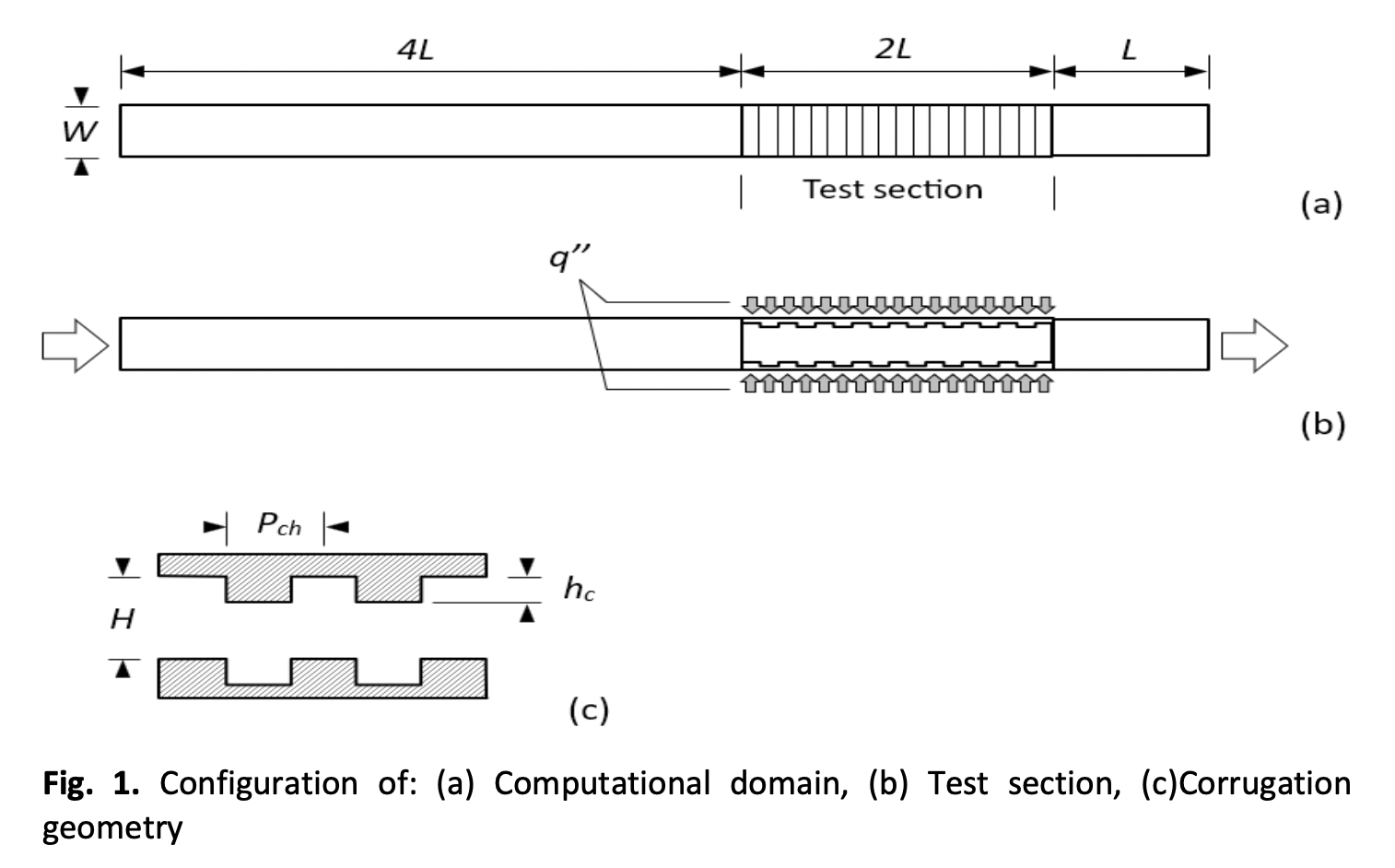

Design and performance of thermal devices are improved by optimizing their geometrical parameters. This study utilized numerical simulation to examine the heat transfer and flow properties of a rectangular corrugated channel at which nanofluid of silicon dioxide (SiO2) and water is flowing. It is determined how the height-to-width ratio (hc/W) and pitch-to-length ratio (pch/L) of a structure affect its thermal and hydraulic properties. The numerical simulations of flow include nanofluids with SiO2-to-water volume fractions of 8% is accomplished by employing the finite volume method (FVM) with SIMPLE algorithm for discretization of the governing equations and coupling of the pressure-velocity system while the k−ε turbulence model was employed to resolve turbulence. The results demonstrate that, in comparison to the (Pch/L) ratio, the (hc/W) ratio has a stronger influence on the enhancement of heat transfer. In reference to the values at minimum Re (Re = 10000), the ratio Pch/L = 0.05 offers the largest increase in Nuav over the Re range by 180.8%. At Reynolds number (Re) 30000, an increase in 99.5% of average Nusselt number (Nuav) is obtained when the (hc/W) ratio is increased from 0.0 to 0.05. The numerical results indicate that the hc/W of 0.05 with a Pch/L of 0.1075 are the optimum parameters and have shown significant improvement in thermal performance criteria (PEC).

Downloads