The Heat Transfer and Fluid Flow Investigations of Single Dimple with Straight and Curved Arch Turbulator within in a Duct

DOI:

https://doi.org/10.37934/arfmts.115.1.206216Keywords:

Heat transfer enhancement, duct flow, vortex generation, dimple surface, forced convectionAbstract

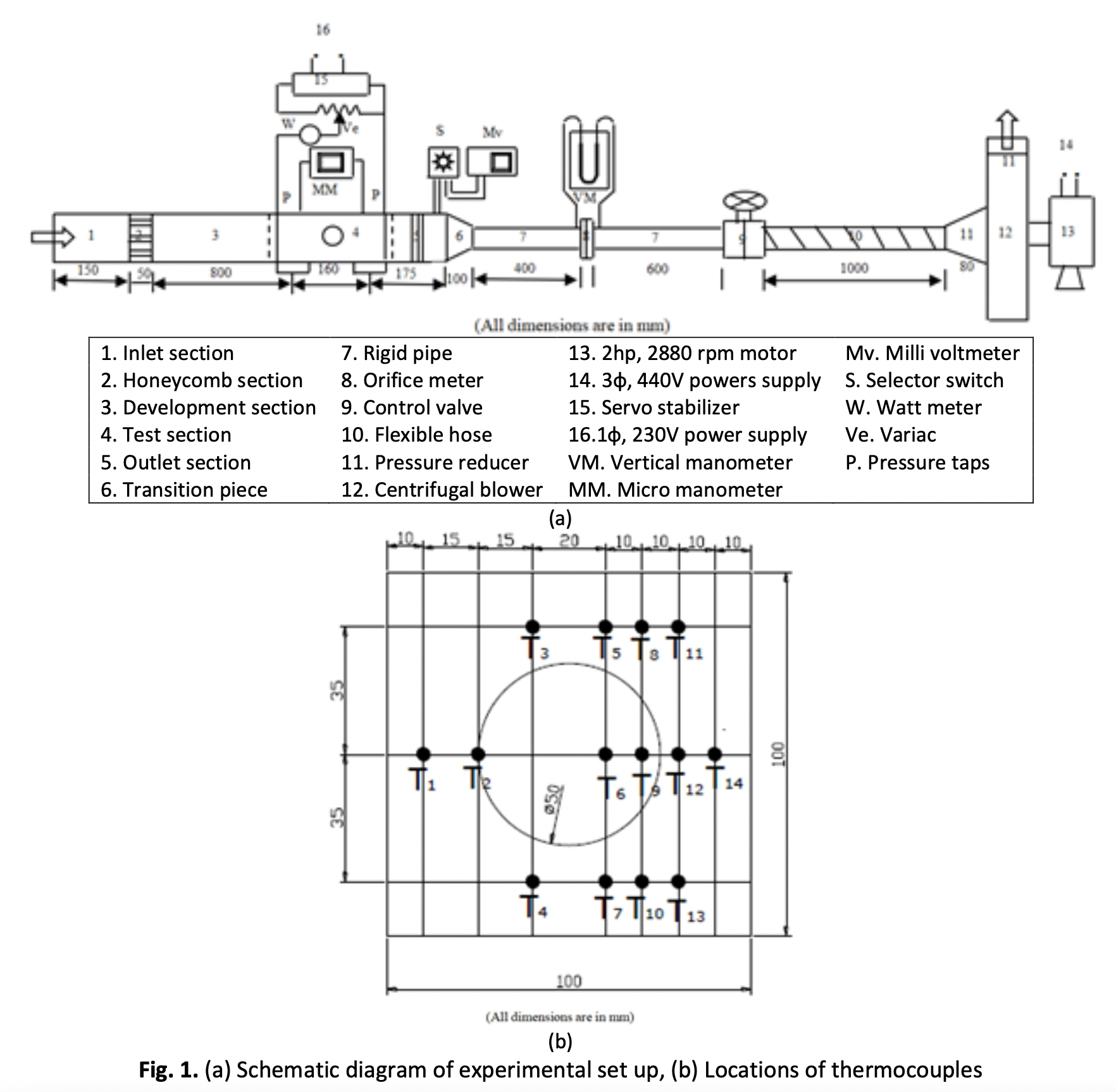

An experimental study was conducted to examine the impact of a single dimple with an arch-type turbulator on heat transfer and fluid friction. The square duct has a 4:1 aspect ratio. Reynolds numbers range from 10,000 to 35,000 depending on hydraulic diameter, maintaining as 0.5 aspect ratio between duct height and dimple diameter. Dimple depth to print diameter ratio is 0.3, which is maintained constant. Two different types of arch turbulators are tested in the first half of the dimple to improve the fluid velocities and heat transfer. The turbulators used in the investigations are both curved and straight type. Curved arch turbulators included angles are 45°, 60°, or 90°, whereas straight arch turbulators are inclined to the surface at a 12° angle. At the dimple's leading edge, an arch turbulator is installed. The experimental findings are displayed as Nusselt number, normalized Nusselt number, friction factor, normalized friction factor, and thermal performance. According to the experimental findings, turbulators with a 60° curved arch operate better than those with 45° and 90° curved arches. Compared to all other arch turbulators, the straight arch turbulator achieves the highest thermal performance.

Downloads