Characterization and Machinability Studies of Aluminium-based Hybrid Metal Matrix Composites – A Critical Review

DOI:

https://doi.org/10.37934/arfmts.101.2.137163Keywords:

Hybrid metal matrix composite, machinability, turning, cutting parameters, optimizationAbstract

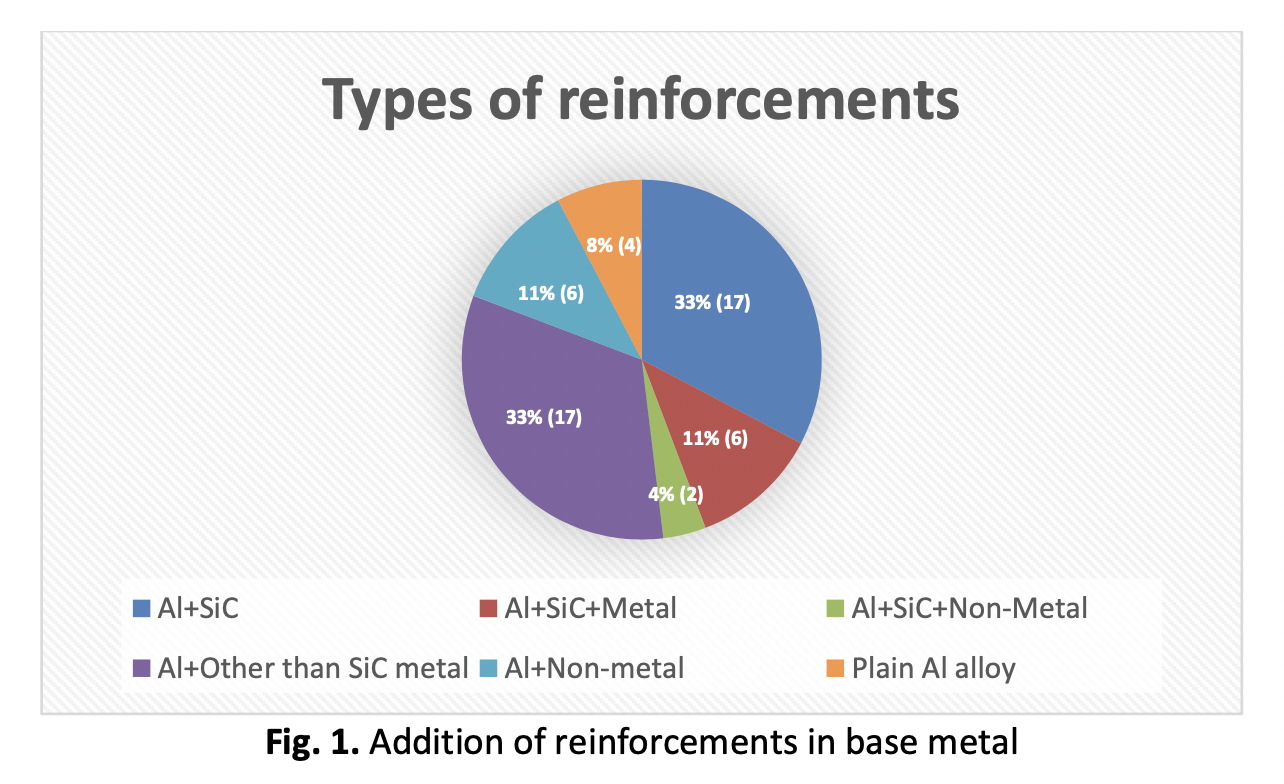

Metal matrix composites (MMCs) are attracting automobile and aeronautical sector because of their superior mechanical and physical characteristics which ultimately reduce the weight of components and hence the energy requirements. These composites are prepared by adding various reinforcements into the base metal by the methods like stir casting, squeeze casting, stir and squeeze casting, sand casting, in-setu method, powder metallurgy etc. When more than one particle is added into the base metal; these composites are called as Hybrid Metal Matrix Composites (HMMCs). The machinability of these hard to cut materials is a challenging task in front of manufacturing industry. Present study considers turning operation of HMMC done on either lathe or CNC machine by using different cutting tool materials. This review focuses on effect of various cutting parameters like speed, depth of cut, feed and also the parameters like reinforcement particle type, particle size and weight percentage on the machinability issues like surface roughness, MRR, cutting forces, tool wear etc. Further the various optimization methods used to suggest the cutting parameters to obtain minimum surface roughness, minimum cutting forces, minimum tool wear and maximum Material Removal Rate (MRR) are addressed.

Downloads