CFD Analysis and Development of Mixing Tank Design for The Fermented Starch Production Process

DOI:

https://doi.org/10.37934/cfdl.16.1.95106Keywords:

Stirred fermenter tank, CFD, impeller, power reductionAbstract

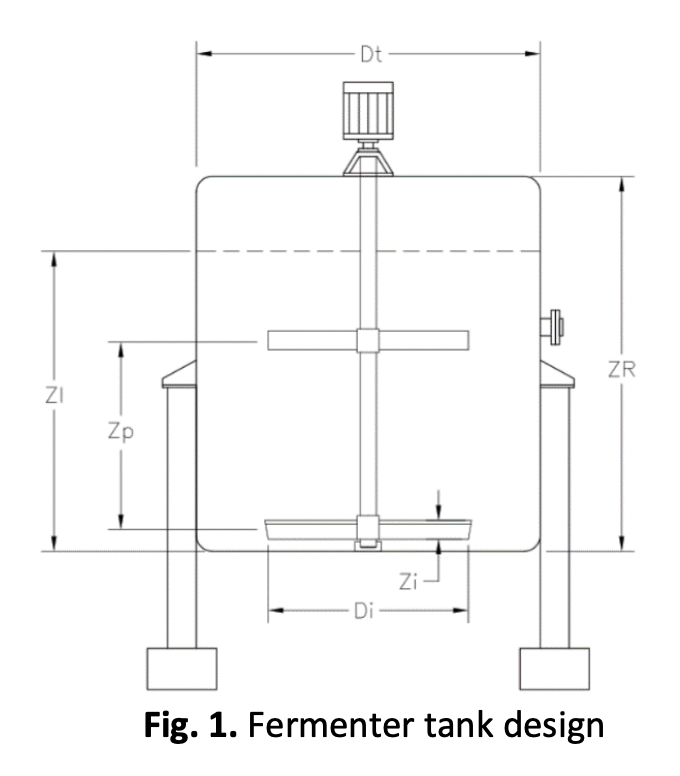

Stirred tanks are widely used in the industrial world, design and improvements are still being developed, including the stirred fermenter tank. A numerical study was carried out to examine the relationship between experimental and reference and computational analysis, in order to minimize the power consumption of a stirred fermenter tanks and optimize the velocity distribution and its profile in radial and axial direction. Specifically, velocity distribution profile in radial and axial direction and the profile of pressure distribution of an experimental impeller, a flat impeller, and a flat-hole impeller were investigated using Computational Fluid Dynamic (CFD) analysis. It was found that the axial velocity at the top and the bottom of the experimental impeller was highly disparate at around 0.95 m/s, while the flat impeller and the flat-hole impeller experienced a disparity of 0.05 m/s and 0.21 m/s, respectively. In case terms of decreased power, the experimental impeller showed power reduction of 21%, greater than that of the flat-hole impeller configuration of 17%.

Downloads

References

Fitschen, Jürgen, et al. "Influence of spacing of multiple impellers on power input in an industrial‐scale aerated stirred tank reactor." Chemie Ingenieur Technik 91.12 (2019): 1794-1801. https://doi.org/10.1002/cite.201900121

Mak, Andrew Tsz-Chung. "Solid-liquid mixing in mechanically agitated vessels." University of London, University College London (United Kingdom) (1992).

Torotwa, I. and ji, C. "A study of the mixing performance of different impeller designs in stirred vessels using computational fluid dynamics." Designs 2.1 (2018): 10. https://doi.org/10.3390/designs2010010

Yulianto, Aton, Palupi Tri Widiyanti, et al. “Fermented Starch: Production Testing of Process Stabilization.” Food Science and Nutrition Studies 3 (1): 1. (2019). https://doi.org/10.22158/fsns.v3n1p1

Rase, H.F. Chemical Reactor Design for Process Plant. 1st ed. New York: McGraw Hill Book Company, Inc. (1977).

Patil, Harshal, et al. "CFD simulation model for mixing tank using multiple reference frame (MRF) impeller rotation." ISH Journal of Hydraulic Engineering 27.2 (2021): 200-209. https://doi.org/10.1080/09715010.2018.1535921

Fluent, A. "ANSYS Fluent Theory Guide ANSYS Inc., Canonsburg, PA. 2020, USA: ANSYS."

Shekhar, S. Murthy, and S. Jayanti. "CFD study of power and mixing time for paddle mixing in unbaffled vessels." Chemical Engineering Research and Design 80.5 (2002): 482-498. https://doi.org/10.1205/026387602320224067

Shaheed, Rawaa, Abdolmajid Mohammadian, and Hossein Kheirkhah Gildeh. "A comparison of standard k–ε and realizable k–ε turbulence models in curved and confluent channels." Environmental Fluid Mechanics 19 (2019): 543-568. https://doi.org/10.1007/s10652-018-9637-1

Phumnok, Ekaroek, et al. "Study of Hydrodynamics and Upscaling of Immiscible Fluid Stirred Tank using Computational Fluid Dynamics Simulation." CFD Letters 14.6 (2022): 115-133. https://doi.org/10.37934/cfdl.14.6.115133

Baba, Ahmad Faiq, et al. "Effect of Impeller’s Blade Number on The Performance of Mixing Flow in Stirred Tank using CFD Simulation Method." CFD Letters 14.5 (2022): 33-42. https://doi.org/10.37934/cfdl.14.5.3342

Driss, Zied, et al. "A study of mixing structure in stirred tanks equipped with multiple four-blade Rushton impellers." Archive of Mechanical Engineering 59.1 (2012): 53-72. https://doi.org/10.2478/v10180-012-0004-3

Hoseini, S. S., et al. "Impeller shape-optimization of stirred-tank reactor: CFD and fluid structure interaction analyses." Chemical Engineering Journal 413 (2021): 127497. https://doi.org/10.1016/j.cej.2020.127497

Perivilli, Satish, et al. "Impact of select geometric and operational parameters on hydrodynamics in dissolution apparatus 2 (paddle apparatus): A design of experiments analysis based on computational fluid dynamics simulations." Pharmaceutical Research 39.5 (2022): 919-934. https://doi.org/10.1007/s11095-022-03272-4

Ameur, H. "Energy efficiency of different impellers in stirred tank reactors." Energy 93 (2015): 1980-1988. https://doi.org/10.1016/j.energy.2015.10.084

Wang, Shiji, et al. "Simulation Analysis of Power Consumption and Mixing Time of Pseudoplastic Non-Newtonian Fluids with a Propeller Agitator." Energies 15.13 (2022): 4561. https://doi.org/10.3390/en15134561

Ameur, Houari, Youcef Kamla, and Djamel Sahel. "Data on the agitation of a viscous Newtonian fluid by radial impellers in a cylindrical tank." Data in brief 15 (2017): 752-756. https://doi.org/10.1016/j.dib.2017.10.035

Wu, Mei, et al. "Evaluation and application of efficient CFD-based methods for the multi-objective optimization of stirred tanks." Chemical Engineering Science 263 (2022): 118109. https://doi.org/10.1016/j.ces.2022.118109

Gu, Deyin, et al. "Design of impeller blades for intensification on fluid mixing process in a stirred tank." Journal of the Taiwan Institute of Chemical Engineers 138 (2022): 104475. https://doi.org/10.1016/j.jtice.2022.104475