Effect of Heat Pipe’s Configuration in Managing the Temperature of EV Battery

DOI:

https://doi.org/10.37934/cfdl.15.3.2234Keywords:

Minichannel liquid cooling, lithium-ion batteries, battery thermal management system, electric vehiclesAbstract

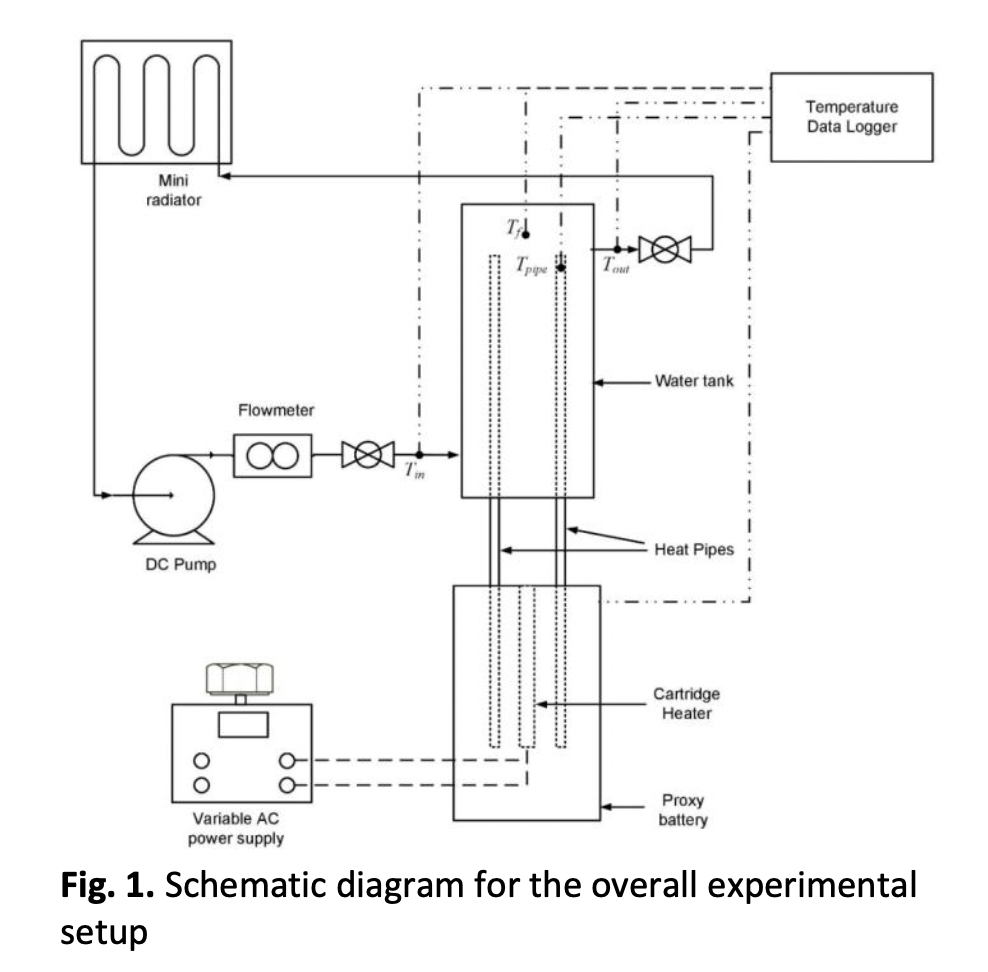

Because of their high energy density and long cycle life, lithium-ion batteries are commonly employed in electric cars. As battery performance and life are highly dependent on temperature, it is critical to maintain the optimum temperature range. A battery thermal management system (BTMS) is critical for controlling the thermal behaviour of the battery. Air cooling, liquid cooling, direct refrigerant cooling, phase change material (PCM) cooling, and heat pipe cooling are all BTMS strategies. Heat pipes come in a variety of sizes and configurations that can be employed in the BTMS and many studies have proven the feasibility of using heat pipe as the electric vehicles’ BTMS. However, there are many aspects of the design and configuration of the heat pipe that could affect the overall thermal performance of the heat pipe BTMS such as its length, diameter, evaporator and condenser lengths, tilt angle, types of heat pipes and working fluids. In this work, a numerical study was conducted to investigate the effect of heat pipe’s diameter, number of heat pipes and the types of heat pipes on the thermal performance of the heat pipe BTMS. The diameter of the heat pipe varies between 6 – 12 mm, the number of heat pipes varies from 2 – 10 and the type of heat pipe considered in this work is straight heat pipe. The thermal performance of the heat pipe is measured by the maximum battery temperature and the thermal resistance at different battery heat generation rate in the range of 10 - 30W. The simulation model was validated against experimental data and results indicate excellent agreement between simulation and experimental data. Simulation results shows that the greater the diameter, the lower is the battery temperature. By increasing the heat pipe’s diameter, the battery temperature can be reduced by at least 10% or 3.4°C. Temperature reduction of at least 12.7% was observed when the number of heat pipes used in the BTMS increases.

Downloads

References

“Data and Statistics: World CO2 emissions,” International Energy Agency, 2020, accessed Apr 27, 2020, https://www.iea.org/data-and-statistics?country=MALAYSIA&fuel=CO2 emissions&indicator=CO2 emissions by energy source.

S. Stapleton, “Oil hits record above $147 - Reuters,” Reuters, accessed Apr. 27, 2020, https://www.reuters.com/article/us-markets-oil/oil-hits-record-above-147-idUST14048520080711.

Ambrose, Jillian. "Oil prices dip below zero as producers forced to pay to dispose of excess." The Guardian 20 (2020),

Goldie-Scot, Logan. "A behind the scenes take on lithium-ion battery prices." Bloomberg New Energy Finance 5 (2019).

Zhao, Jiateng, Zhonghao Rao, and Yimin Li. "Thermal performance of mini-channel liquid cooled cylinder based battery thermal management for cylindrical lithium-ion power battery." Energy conversion and management 103 (2015): 157-165. https://doi.org/10.1016/j.enconman.2015.06.056

Rao, Zhonghao, and Shuangfeng Wang. "A review of power battery thermal energy management." Renewable and Sustainable Energy Reviews 15, no. 9 (2011): 4554-4571. https://doi.org/10.1016/j.rser.2011.07.096

Spotnitz, R., and J. Franklin. "Abuse behavior of high-power, lithium-ion cells." Journal of power sources 113, no. 1 (2003): 81-100. https://doi: 10.1016/S0378-7753(02)00488-3

Pesaran, Ahmad, Andreas Vlahinos, and Thomas Stuart. "Cooling and preheating of batteries in hybrid electric vehicles." In 6th ASME-JSME Thermal Engineering Joint Conference, pp. 1-7. Citeseer, 2003.

Pesaran, Ahmad A. "Battery thermal models for hybrid vehicle simulations." Journal of power sources 110, no. 2 (2002): 377-382. https://doi: 10.1016/S0378-7753(02)00200-8

Huber, C., and R. Kuhn. "Thermal management of batteries for electric vehicles." In Advances in battery technologies for electric vehicles, pp. 327-358. Woodhead Publishing, 2015. https://doi.org/10.1016/B978-1-78242-377-5.00013-3

Wang, Rong-Tsu, Ya-Wei Lee, Sih-Li Chen, and Jung-Chang Wang. "Performance effects of heat transfer and geometry on heat pipe thermal modules under forced convection." International Communications in Heat and Mass Transfer 57 (2014): 140-149. https://doi: 10.1016/j.icheatmasstransfer.2014.07.023

Pesaran, Ahmad A. "Battery thermal models for hybrid vehicle simulations." Journal of power sources 110, no. 2 (2002): 377-382. https://doi: 10.1016/S0378-7753(02)00200-8

Warner, John. "Lithium-ion battery packs for EVs." In Lithium-Ion Batteries, pp. 127-150. Elsevier, 2014. https://doi.org/10.1016/B978-0-444-59513-3.00007-8

Rami, Sabbah, R. Kizilel, and J. R. Selman. "Active vs passive thermal management of high power lithium-ion packs: Limitation of temperature rise and uniformity of temperature distribution." J. Power Sources 182, no. 2 (2008): 630-638. https://doi.org/10.1016/j.jpowsour.2008.03.082

Kim, Jaewan, Jinwoo Oh, and Hoseong Lee. "Review on battery thermal management system for electric vehicles." Applied thermal engineering 149 (2019): 192-212. https://doi: 10.1016/j.applthermaleng.2018.12.020

Khan, Mohammad Rezwan, Maciej Jozef Swierczynski, and Søren Knudsen Kær. "Towards an ultimate battery thermal management system: A review." Batteries 3, no. 1 (2017): 9. https://doi: 10.3390/batteries3010009

Septiadi, Wayan Nata, Fazlur Rahman, Made Ricki Murti, Komang Wahyu Tri Prasetia, Gerardo Janitra Puriadi Putra, Luh Putu Ike Midiani, and Nandy Putra. "Thermal Resistance of Cascade Heat Pipe as CPU Cooling System to Maintain Safe Temperature for Computer." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 81, no. 1 (2021): 165-173. https://doi.org/10.37934/arfmts.81.1.165173

Rahim, Nasrullah Che, Muhammad Fairuz Remeli, Baljit Singh, and Hazim Moria. "Designing a Solar Heat Storage System using Heat Pipe and Phase-Change Material (PCM)." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 91, no. 1 (2022): 102-114. https://doi.org/10.37934/arfmts.91.1.102114

Hanoin, Mohd Amirul Hilmi Mohd, Nor Amirah Safiah Muhamad, Nadzirah Mohd Mokhtar, Amir Abdul Razak, and Muhamad Sukri Hadi. "Effect Of Design Parameters of Serpentine-Shaped Flat Plate Solar Collector Under Malaysia Climate Conditions." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 88, no. 1 (2021): 71-80. https://doi.org/10.37934/arfmts.88.1.7180

Swanepoel, Gerhardus. "Thermal management of hybrid electrical vehicles using heat pipes." PhD diss., Stellenbosch: Stellenbosch University, 2001.

Wu, Mao-Sung, K. H. Liu, Yung-Yun Wang, and Chi-Chao Wan. "Heat dissipation design for lithium-ion batteries." Journal of power sources 109, no. 1 (2002): 160-166. https://doi: 10.1016/S0378-7753(02)00048-4

Zhao, Rui, Sijie Zhang, Jie Liu, and Junjie Gu. "A review of thermal performance improving methods of lithium ion battery: Electrode modification and thermal management system." Journal of Power Sources 299 (2015): 557-577. https://doi: 10.1016/j.jpowsour.2015.09.001

Deng, Shasha, Kuining Li, Yi Xie, Cunxue Wu, Pingzhong Wang, Miao Yu, Bo Li, and Jintao Zheng. "Heat pipe thermal management based on high-rate discharge and pulse cycle tests for lithium-ion batteries." Energies 12, no. 16 (2019): 3143. https://doi: 10.3390/en12163143

Ye, Xin, Yaohua Zhao, and Zhenhua Quan. "Experimental study on heat dissipation for lithium-ion battery based on micro heat pipe array (MHPA)." Applied Thermal Engineering 130 (2018): 74-82. https://doi: 10.1016/j.applthermaleng.2017.10.141

Zhao, Rui, Junjie Gu, and Jie Liu. "An experimental study of heat pipe thermal management system with wet cooling method for lithium ion batteries." Journal of power sources 273 (2015): 1089-1097. https://doi: 10.1016/j.jpowsour.2014.10.007

Zhang, Wencan, Jieyu Qiu, Xiuxing Yin, and Daoyong Wang. "A novel heat pipe assisted separation type battery thermal management system based on phase change material." Applied Thermal Engineering 165 (2020): 114571. https://doi: 10.1016/j.applthermaleng.2019.114571

Dan, Dan, Chengning Yao, Yangjun Zhang, Hu Zhang, Zezhi Zeng, and Xiaoming Xu. "Dynamic thermal behavior of micro heat pipe array-air cooling battery thermal management system based on thermal network model." Applied Thermal Engineering 162 (2019): 114183. https://doi: 10.1016/j.applthermaleng.2019.114183

Liu, Feifei, Fengchong Lan, and Jiqing Chen. "Dynamic thermal characteristics of heat pipe via segmented thermal resistance model for electric vehicle battery cooling." Journal of Power Sources 321 (2016): 57-70. https://doi: 10.1016/j.jpowsour.2016.04.108

Tran, Thanh-Ha, Souad Harmand, and Bernard Sahut. "Experimental investigation on heat pipe cooling for hybrid electric vehicle and electric vehicle lithium-ion battery." Journal of power sources 265 (2014): 262-272. https://doi: 10.1016/j.jpowsour.2014.04.130

Tran, Thanh-Ha, Souad Harmand, Bernard Desmet, and Sebastien Filangi. "Experimental investigation on the feasibility of heat pipe cooling for HEV/EV lithium-ion battery." Applied Thermal Engineering 63, no. 2 (2014): 551-558. https://doi: 10.1016/j.applthermaleng.2013.11.048

Rao, Zhonghao, Shuangfeng Wang, Maochun Wu, Zirong Lin, and Fuhuo Li. "Experimental investigation on thermal management of electric vehicle battery with heat pipe." Energy Conversion and Management 65 (2013): 92-97. https://doi: 10.1016/j.enconman.2012.08.014

Wang, Tao, K. J. Tseng, Jiyun Zhao, and Zhongbao Wei. "Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies." Applied energy 134 (2014): 229-238. https://doi: 10.1016/j.apenergy.2014.08.013

Ye, Yonghuang, Yixiang Shi, Lip Huat Saw, and Andrew AO Tay. "Performance assessment and optimization of a heat pipe thermal management system for fast charging lithium ion battery packs." International Journal of Heat and Mass Transfer 92 (2016): 893-903. https://doi: 10.1016/j.ijheatmasstransfer.2015.09.052

Krisangsri, Poomin, Teerasak Hudakorn, and Noppong Sritrakul. "Effect of Internal Diameter and Working Fluids on Thermal Performance of a Vertical Closed-Loop Oscillating Heat Pipe with Double Heat Sources." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 82, no. 2 (2021): 120-126. https://doi.org/10.37934/arfmts.82.2.120126

Abdullahi, Bala, Ahmed Elsayed, Raya Al-Dadah, Sa'ad Mahmoud, Abdel Fateh Mahrous, Nura Mu'az Muhammad, and Saidu Bello Abbakar. "Experimental and numerical investigation of thermosyphon heat pipe performance at various inclination angles." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 44, no. 1 (2018): 85-98.

Putra, Nandy, Adi Winarta, Raldy Artono Koestoer, Agus Sunjarianto Pamitran, and Imansyah Ibnu Hakim. "Heat transfer performance of oscillating heat pipe with ethanol and methanol working fluid with different inclinations for heat recovery application." Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 57, no. 2 (2019): 148-157.

Nasir, Faiza M., Mohd Z. Abdullah, and Mohd A. Ismail. "Experimental investigation of water-cooled heat pipes in the thermal management of lithium-Ion EV batteries." Arabian Journal for Science and Engineering 44, no. 9 (2019): 7541-7552. https://doi: 10.1007/s13369-019-03851-5