Exploring the Potentials of Copper Oxide and CNC Nanocoolants

DOI:

https://doi.org/10.37934/araset.34.2.315326Keywords:

Nano coolant, automobile radiator, compact enginesAbstract

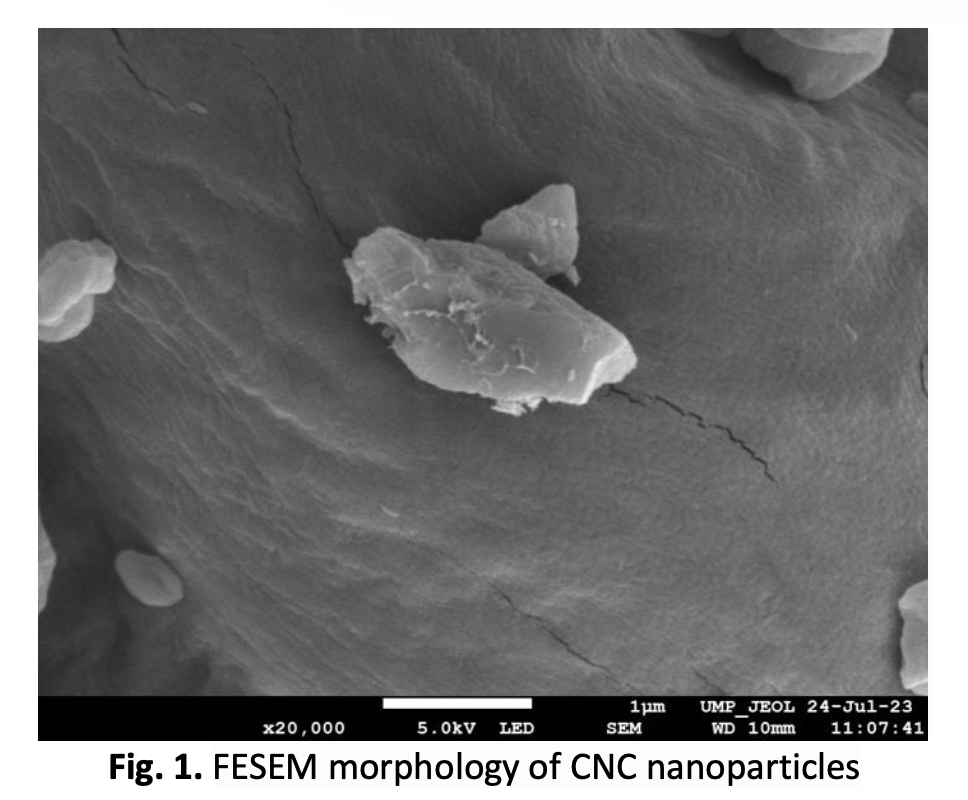

The characteristics, stability, kinematic viscosity, viscosity index, thermal conductivity, and specific heat changes of Copper Oxide (CuO) and Cellulose Nanocrystal (CNC) hybrid nanocoolants at low concentrations are investigated in this work. The hybrid nanocoolants were created using different ratios of CNC and CuO nanoparticles and compared to single nanoparticle coolants. The existence of Cu-O and other similar formations was verified using Fourier Transform Infrared Spectroscopy (FTIR). Visual examination and UV Spectrophotometry stability study revealed that the nanocoolants were stable for up to 8 weeks, with little precipitation seen for single nanoparticle coolants after 12 weeks. When tested against temperature, kinematic viscosity decreased with increasing temperature, with very minor differences amongst coolants. The results of the Viscosity Index (VI) indicated that the hybrid nanocoolant performed similarly to the basic fluid, Ethylene Glycol (EG), even at high temperatures. Thermal conductivity rose as temperature increased, with a single CuO nanocoolant and a CNC:CuO (80:20) hybrid having the maximum conductivity. Specific heat capacity measurements revealed a declining trend as temperature rose. Overall, the CNC:CuO (80:20) hybrid nanocoolant and the CuO single nanocoolant displayed improved characteristics and stability, suggesting their potential for increased heat transfer applications.

Downloads