Friction Comparison and Wear Analysis of Ceramic Cutting Tools Made from Alumina-Zirconia- Chromia Content

DOI:

https://doi.org/10.37934/aram.112.1.175182Keywords:

Ceramic cutting tool, Friction, Machining, wear mechanism, wear formationAbstract

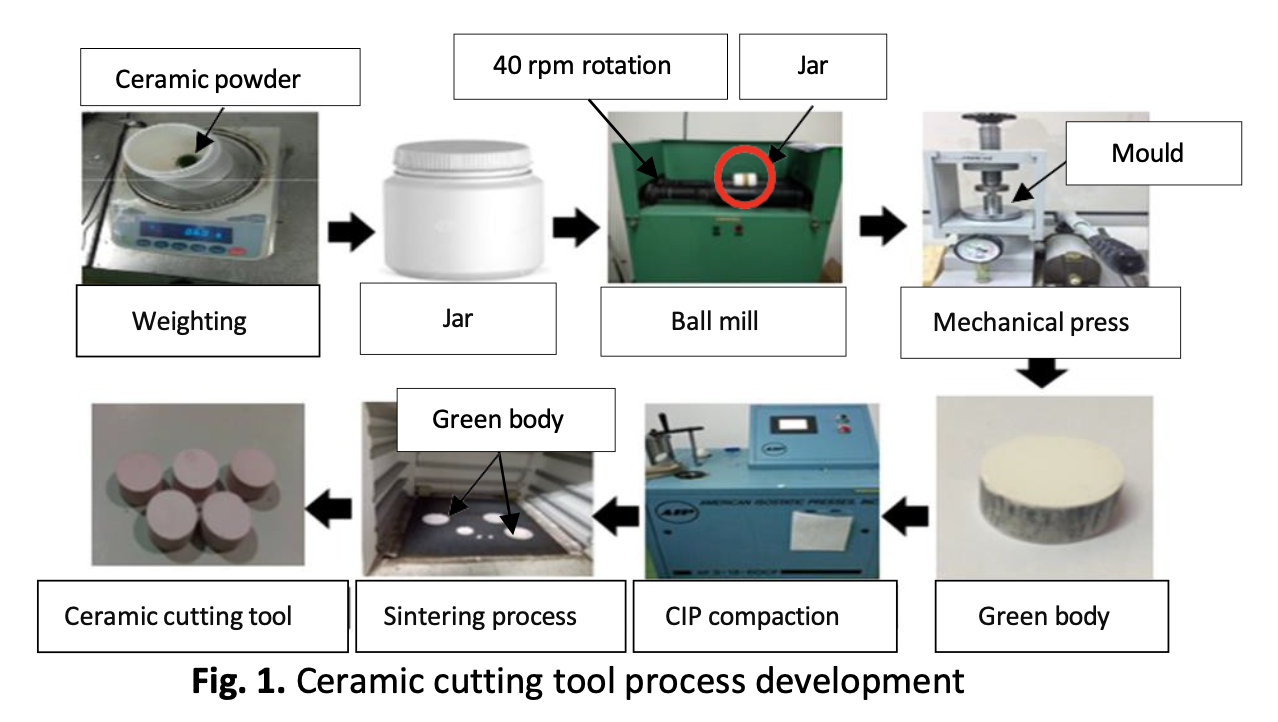

This research focused on wear analysis by using the coefficient of friction (COF) and high-speed CNC turning machine against ceramic cutting tools made from 80 wt.% Al2O3 - 20 wt.% ZrO2 mixed with 0.2 - 0.8 wt.% Cr2O3. The results showed that the sample with a composition ratio of 80 wt.% Al2O3 – 20 wt.% ZrO2 – 0.6 wt.% Cr2O3 demonstrated the lowest coefficient of friction of 0.305. In terms of tool wear, this cutting tool showed uniform abrasion marks on the flank wear, resulting in 60% - 80% better tool life compared to Al2O3 and Al2O3-ZrO2. Based on the observation by using SEM, analyses showed that grains were tightly bound to each other at a high cutting speed of 350 m/min and with a feed rate of 0.175 mm/rev, compared to Al2O3 and Al2O3- ZrO2 which showed visible chipping and notch. The addition of 0.6 wt.% Cr2O3 on Al2O3-ZrO2 composition was enough to increase the strength and reliability against ceramic cutting tools for machining purposes.

Downloads